Protecting Vancouver Roofs with Advanced Technology

Our Mission:

EcoRenew Roof Services brings cutting-edge roof rejuvenation technology to the Lower Mainland, helping homeowners extend their roof's life, save thousands of dollars, and make environmentally responsible choices for their homes.

Why We Do This:

Every year, millions of asphalt shingles end up in landfills prematurely. Many of these roofs could have been restored to like-new condition with proper treatment. We're passionate about changing that through advanced roof science and preventive care.

Trusted & Certified

Precision Roof Repairing, Guaranteed!

Our Expertise

Licensed & Certified Partners

- Factory-trained in advanced roof rejuvenation technology

- Licensed and insured for your protection

- Certified drone operators for safe, detailed inspections

- Ongoing training in latest roof restoration techniques

Local Vancouver Knowledge

- Deep understanding of Lower Mainland climate challenges

- Experience with regional roof types and common issues

- Established relationships with local suppliers and contractors

- Commitment to serving our community

Our Process Standards

Quality Assurance:

- Every technician factory-certified

- Standardized application procedures

- Quality control at every step

- Customer satisfaction guarantee

Safety First:

- Licensed and insured operations

- Drone technology reduces roof access risks

- Environmentally safe products only

- Proper safety equipment and procedures

Service Areas

Proudly Serving: Vancouver, Burnaby, Richmond, Surrey, Coquitlam, Port Coquitlam, Langley, New

Westminster, North Vancouver, West Vancouver, and surrounding Lower Mainland communities.

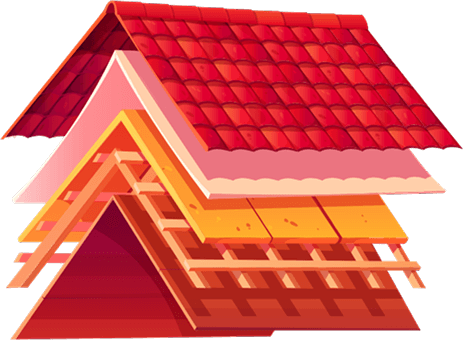

How it works

We understand that your business is valuable

Transform your commercial property with our comprehensive roofing solutions. From emergency repairs to complete roof installations, we bring expertise, innovation, and a results-driven approach to every project.

Request & Consultation

Start by contacting us online or by phone to describe your roofing needs. Our expert team will schedule a convenient appointment for a free on-site inspection and consultation to assess your industrial or commercial property.

Detailed Assessment & Proposal

Our certified roofing specialists will thoroughly examine your roof, identify any issues, and provide a comprehensive assessment. You'll receive a detailed proposal outlining recommended solutions, materials, timeline, and transparent pricing.

Expert Installation & Quality Assurance

We execute your roofing project with precision and care using industry-leading materials and techniques. Upon completion, we conduct a thorough inspection, provide maintenance recommendations, and offer an industry-leading warranty on both materials and workmanship.

Reach out to us anytime with any request

Whether you require an emergency repair, a detailed roof assessment, or professional consultation, Motivix Industrial Roofing is always ready to deliver exceptional service.

24/7 Emergency Response

Motivix offers round-the-clock emergency support with guaranteed 4-hour response times for critical roofing issues at commercial and industrial facilities.

Fully Insured & Certified

All roofing services by Motivix are backed by $5M liability coverage and manufacturer certifications, guaranteeing safe, compliant, and protected project execution.

Detailed Assessment

Request your comprehensive roof evaluation from Motivix to receive a detailed condition report, thermal scans, and cost-effective, tailored roofing solutions.

TESTIMONIALS

What Our Client Says

About Us

Robert HargroveChicago

Michael ChenHouston

Sarah LawsonDenver

Nicolas lowsonLand Owner

FAQ

Frequently Asked Questions

Explore Motivix Industrial Roofing's expertise, specialized systems, and industry-leading practices for durable commercial and industrial roofing solutions.